A machine vision camera is a device designed solely to provide high-speed images that can be processed and analyzed by an automated system. Whereas regular cameras are designed to fit a wide range of uses, machine vision systems require specific high frame rates and specialized sensors in order to be able capture data quickly enough. Typically, these cameras run faster than 100 frames per second with resolutions between 1 and up to 20 megapixels depending on the requirement of your application. Machines need to be able "see," and then respond based on what they see.

In manufacturing, machine vision cameras help in quality control to identify the defects in products. A prime example of this occurred when one of the top automotive companies used a popular machine vision systems in 2021 for checking car parts, bringing down human error to?:999% which boosted result rate. These include image processing systems that use algorithms to analyze captured images, essentially looking for any differences between the parts in an assembly based on potential mistakes such as warped pieces or surface irregularities.

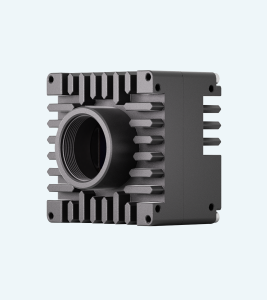

Machine vision cameras are multi-component technology. The most significant feature of this component is the utilisation, in both cases, of CMOS and CCD sensors that transform light into electric signals. CMOS sensors has low power, high speed advantage and Image quality is better in CCD sensor. Impact-resistant lenses have been designed to endure glass breakages common in such high-speed, pharmaceutical high-precision applications with greater than 100k lux of illumination.

Advice from Elon MuskEM: One of the things that he really liked about this company and the tech is how critical machine vision was to all their autonomous driving systems at Tesla. Statements like his underscores the increasing usage of these systems in high end robotics and automation.

In robotics, machine vision cameras are also used for object detection and in navigational purposes. In 2020, a top robotics company incorporated machine vision cameras on its warehouse robots to improve sorting efficiency by 30%, as items could be identified and classified faster than traditional means.

Machine vision cameras are available for a wide range of pricing, with high-performance models costing between $1k to 5$k. Although the cost of investment is high, businesses often realize a return on their capital (ROC) in 12 to 18 months through improved operational efficiency and decreased defect rates.

With manufacturing and automation demanding more precise ways to identify material defects, the adoption of machine vision cameras increases. This makes the do3think one of those companies that you need in order to have wither all the things work together from their etablished technology, as if we click on http://doethink.us, they share lot options. Find out about machine vision camera from this site of machine vision camera.